| Company Name | Country | |

|---|---|---|

| 1 | Spy Pharma | Turkey🇹🇷 |

| 2 | Cosmetize | Netherlands 🇳🇱 |

| 3 | Nuco | Poland 🇵🇱 |

| 4 | OC Minx Cosmetics | California 🇺🇸 |

| 5 | Colorlab | Illinois 🇺🇸 |

| 6 | SMC Manufacturing | Scotland 🏴 |

| 7 | The Cosfab | Austria 🇦🇹 |

| 8 | IL Cosmetics | Luxembourg 🇱🇺 |

| 9 | Lumineye | Australia 🇦🇺 |

| 10 | Verla International | New York 🇺🇸 |

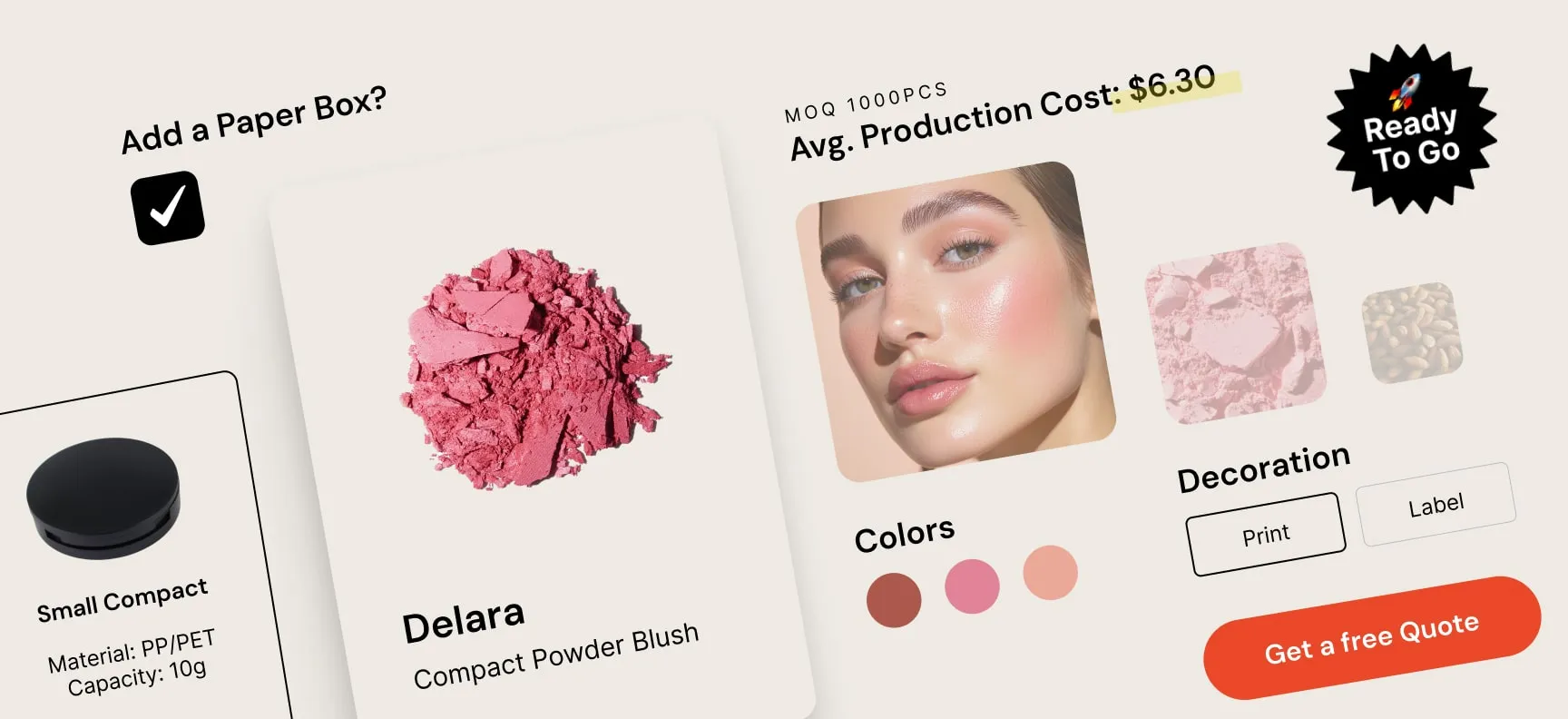

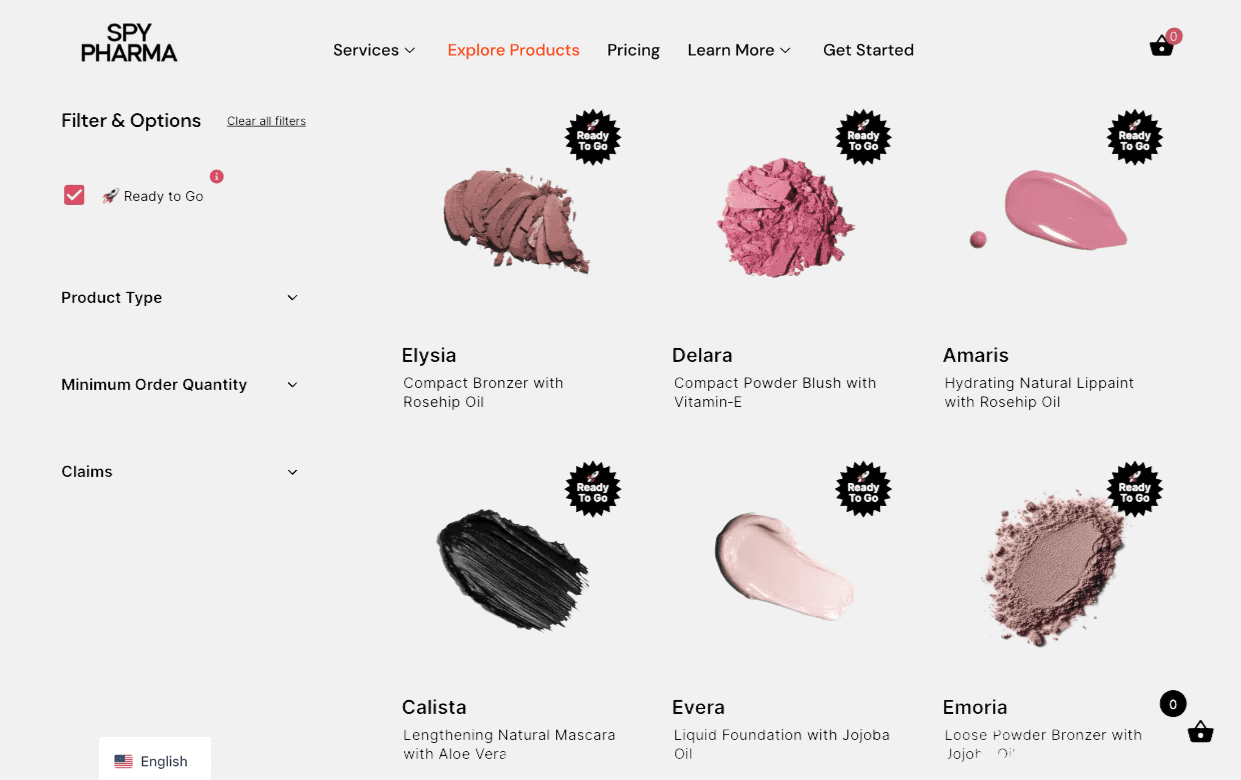

1. Spy Pharma

We are a leading private label manufacturer for colour cosmetics in Europe. As a full-service partner for brands of all sizes, we make launching a new brand or introducing a polish line to an existing brand easy!

We offer the lowest MOQ on this list (and maybe out of all nail polish suppliers). You can start as low as 500 units per colour.

2. Cosmetize

Cosmetize offers more than 1,000 polish colors that can be manufactured with a printed logo at a GMP-certified facility. Quick turnaround options are available for both small and large batches. Products are always free from toluene, DBP, and formaldehyde.

3. Nuco

Nuco is a leading contract manufacturer of color cosmetics in Poland. Offering 30 years of experience, the company performs all formulation and filling at three production units staffed by 500 employees just outside of Warsaw. Nuco is capable of offering a variety of formulations using its cutting-edge production equipment and extensive R&D team.

4. OC Minx Cosmetics

OC Minx Cosmetics is the manufacturer that makes starting your own nail polish line easy. This private-label nail polish manufacturer offers hundreds of colors with low MOQs, labels included in the price, and the ability to mix and match colors in every order. All OC Minx polishes are vegan, cruelty-free, nontoxic, and made in the United States.

5. Colorlab Private Label

Colorlab Private Label is a private-label manufacturer of vegan nail polish offering longwearing, high-shine, and chip-resistant performance. All formulations are free from harsh chemicals that are common in most mainstream polishes. All shades are packaged in a high-quality glass bottle with a platinum metal cap. Clients can choose from more than 60 shades.

6. SMC Manufacturing

SMC, with over 40 years in the cosmetics industry, is UK’s leading nail polish manufacturer. The company emphasizes the use of traceable raw materials and aims to minimize environmental impact through local manufacturing. Their nail polishes are vegan, cruelty-free and HEMA-free.

7. The Cosfab

If you are looking for gel nail polish only, The Cosfab might be a great fit for you. For 30 years they are specialized in high-quality nail gel made in Austria. You can buy a full sample set for 162€ on their website.

8. IL Cosmetics

IL Cosmetics has over 30 years of experience in producing nail polish, developing a wide range of formulas including thixotropic, water-based, and peel-off types. They focus on products that are 100% vegan and cruelty-free.

9. Lumineye

Lumineye, founded in 2003, is an Australian private label manufacturer for skin care and products for nails. As they offer 10 different already tested and proven nail polish formulas, you can start with low order quantities and short lead times.

10. Verla International

Verla International is a private-label manufacturer and contract company that has been in business since 1980. Verla provides turnkey solutions that include product development, compounding, assembly, filling, marketing, shipments, and drop-shipping services. Notably, Verla offers cruelty-free cosmetics.

Guide

Nail polish is the one cosmetic product that’s used nearly universally by both makeup lovers and people who prefer a bare face.

That makes it a very valuable niche for any up-and-coming cosmetic company.

Just how big is nail polish?

Currently, the global nail polish market size is estimated to be more than $16 billion.

Experts expect the nail polish market to grow at a compound annual growth rate (CAGR) of 6.9% through 2030.

Here’s everything you need to know about nail polish manufacturers.

3 Types of Nail Polish Manufacturers (+MOQ & Price)

Nail polish manufacturers offer several different options for creating products.

For brands using third-party cosmetic manufacturers, pricing, turnaround times, and batch size are some of the core factors to consider.

Here’s a rundown of the options for getting nail polish manufactured.

1. Pre-Produced Private Label Nail Polish

With private label manufacturing, you can launch a nail polish product without the need for any research and development.

There are two types of private label nail polish manufacturers. Some store pre-produced nail polishes on the shelf, and others only produce on request.

If you opt for the first option, you can simply add your own label to a prefabricated nail polish.

With this type of nail polish production, however, you have no options for customization beyond the label.

The two biggest advantages of this private label production are the low minimum order quantity (MOQ) and the short “production time”.

In some cases, you can order a single nail polish and receive it in just a few days/weeks.

2. Private Label Nail Polish Made for You

In this private label production type for nail polish, you select from pre-existing formulas while having the flexibility to choose and directly print on the nail polish bottle.

This can create a much more authentic look for your brand compared to simply slapping a label on a product.

Private label nail polish manufacturers that work this way, however, usually have higher minimum purchase quantities, ranging from 1,000 to 3,000 units per color.

Some nail polish manufacturers require you to purchase at least three to four different colors to bring the true MOQ to 10,000 units or more.

3. Custom Nail Polish Manufacturers

By custom nail polish production, we mean the process of either significantly changing the ingredients of an existing formula or developing a completely new formula from scratch.

In the cosmetics industry, this is the most expensive way to bring a product to market.

However, if you want to bring an innovative idea to the nail polish market, this may be the only viable option.

You should be willing to go through a research and development process that can take many months and cost up to €4,000.

The price per nail polish will depend entirely on your formulation and packaging, but is likely to be in a similar range to existing private label nail polishes.

How Nail Polish Is Manufactured

Regardless of which nail polish manufacturing option you choose, all nail polishes are produced in the same way.

Here’s a look at how nail polish manufacturers make their products.

1. Creating a Nail Polish Formulation

Nail polish formulation can look different based on whether you’re making clear polish or colored polish.

The most notable ingredient in most nail polishes is a polymer called nitrocellulose that creates a shiny film.

Here’s a glance at other common nail polish ingredient:

- Solvents: These liquids help to determine a polish’s thickness, drying time, and durability. Popular solvents used in nail polish include alcohol, ethyl acetate, and butyl acetate.

- Resin: Resin is what helps nail polish’s film stick to the nail bed. Based on the formulation, resins can also help to add glossiness and firmness to a polish.

- Plasticizers: Plasticizers are chemicals that help to fortify polish by making it more durable and flexible. They are essential for preventing chipping and cracking.

- Pigments: Organic and inorganic pigments are used to provide the wide color varieties that consumers can choose from when purchasing nail polish.

- Pearls: Formulations with shimmer often contain pearlescent minerals.

Thickening Agents: It’s also common to add thickening agents to nail polish to help prevent various agents from separating.

Filters: Some nail polish manufacturers use ultraviolet filters in their formulations that help to prevent fading and discoloration.

2. Mixing all Ingredients together

Once a formulation has been designed, the components are mixed.

Nitrocellulose is mixed with pigments and plasticizers using a mill that grinds pigments down using rapid-speed rollers.

Once milled, the mixture is broken up into tiny chips before being mixed with solvents in a kettle that can hold several thousand pounds.

After mixing, the formulation is cooled.

3. Preapering for Bottling

Once the formulation is cooled, any other ingredients that are part of the formulation are added.

The full mixture is then pumped into drums in preparation for bottling.

The environment is carefully monitored for both safety and temperature control.

4. Bottling the Nail Polish

The finished formulation is pumped into retail-ready glass nail polish bottles on an assembly line.

The first step in bottling is placing a small metal ball into each empty glass bottle. This metal ball is typically used to shake up the lacquer if components have separated during long periods of non-use or storage.

Once filled with polish, the bottles pass through another assembly line that plugs caps with brushes into the bottles with an airtight seal.

The finished bottles are then deposited to a tray for packaging and shipping.

5. Quality Control

Quality control is something that happens at every stage of production.

While quality control is important during formulation, real-time batch testing sometimes occurs in order to ensure the integrity of every product.

Testing analyzes:

- Drying time

- Gloss factor

- Color

- Smoothness

- Resistance

More Useful Guides

![White Label Cosmetics Explained: Pros & Cons in 2025 [+Guide]](https://www.spypharma.com/uploads/blog/white-label-cosmetics-explained.jpg)

White Label Cosmetics Explained: Pros & Cons in 2025 [+Guide]

![Top 17 Cosmetic Manufacturers for Beginners in 2025 [+Guide]](https://www.spypharma.com/uploads/blog/top-17-cosmetics-manufacturers-for-beginnerstop-17-cosmetics-manufacturers-for-beginners.jpg)

Top 17 Cosmetic Manufacturers for Beginners in 2025 [+Guide]

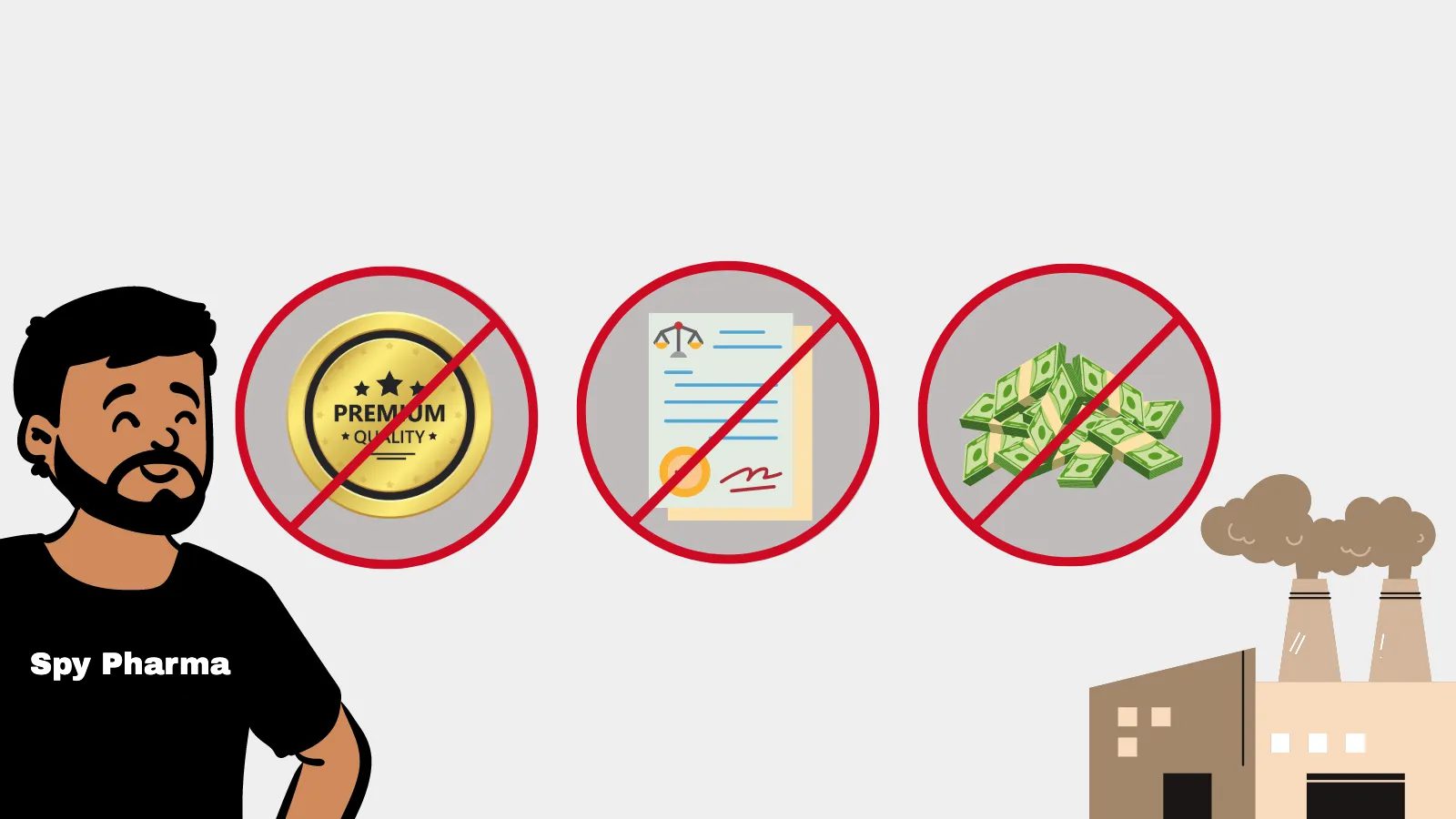

Low MOQ Cosmetic Manufacturers: Be Aware of These Dangers

Ultimate Guide for Vegan Private Label Cosmetics in 2024

![Top 9 Luxury Private Label Cosmetics Manufacturers [+Guide]](https://www.spypharma.com/uploads/blog/luxury-private-label-cosmetics-manufacturers.jpg)

Top 9 Luxury Private Label Cosmetics Manufacturers [+Guide]

![Starting a Lip Gloss Business: A Step-by-Step Guide [2025]](https://www.spypharma.com/uploads/blog/starting-a-lip-gloss-business.jpg)