Have you ever wondered how your favorite lipstick or foundation is actually made?

It’s not just mixing some colors together.

The process is way more interesting than you might think. In this post, we’ll break down how makeup is made, straight from the source — as we are a cosmetic manufacturer.

From the ingredients that go into your makeup to the steps taken to turn them into products you use every day, we’ll cover it all.

Let’s pull back the curtain on the beauty industry and see what really goes into making that perfect shade of lipstick.

What are Private Label Skin Care Manufacturers?

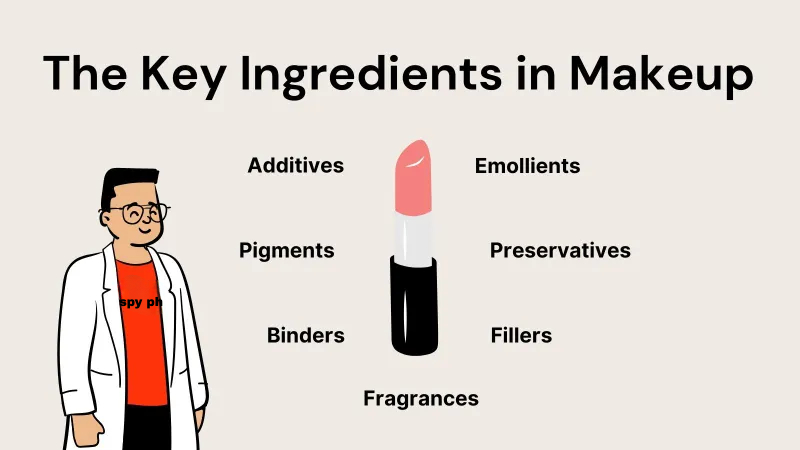

The foundation of any great makeup product lies in its ingredients. Each component plays a specific role, from adding color to getting a smooth application.

Understanding these key ingredients helps you to better understand ingredient lists and assess the composition of a cosmetic product

1. Pigments

Pigments are what give makeup its color. They are essential in all color cosmetic products like lipstick, eyeshadow, and foundation.

There are two main types: natural and synthetic. Natural pigments come from minerals or plants, while synthetic pigments are made in labs. Synthetic pigments offer a broader range of colors and often last longer.

For example, to create a deep red lipstick, a manufacturer might start with iron oxide, a natural pigment known for its earthy red tones. They might then add a touch of titanium dioxide to lighten the shade slightly and give it more opacity. To enhance the richness of the color, they could blend in a small amount of a synthetic pigment like D&C Red 7.

Each pigment is measured and mixed until the exact shade is achieved. The final result is a bold red that’s consistent in every unit.

Common Pigments:

2. Emollients

Emollients are ingredients that make makeup feel smooth and help it glide onto the skin. They also help keep the skin hydrated by locking in moisture.

For example, in a creamy foundation, a manufacturer might use jojoba oil as the emollient. This oil helps the foundation spread easily on the skin and leaves a soft, non-greasy finish.

The right amount of emollient is crucial; too much can make the product feel oily, while too little can make it hard to apply.

Emollients also play a role in how long the makeup lasts on the skin, making them an important part of the formulation process.

Common Emollients:

3. Binders

Binders are essential in keeping makeup products stable and intact. They ensure that powders stay compacted and creams maintain their smooth texture. Binders prevent products from crumbling or separating, which is crucial for both powder and cream-based makeup.

For example, in a pressed eyeshadow, beeswax might be used as a binder. It helps the powder particles stick together, so the product stays solid in its container but still applies smoothly on the skin.

Common Binders:

4. Preservatives

Preservatives are added to makeup to stop bacteria, mold, and yeast from growing. They could spoil the product and cause skin issues. Since makeup often come into contac with air and skin, preservatives help keep the product safe and usable for longer.

For example, in a liquid foundation, phenoxyethanol is often added to prevent microbial growth. This helps the foundation remain fresh and safe to use for months, instead of just weeks. Without preservatives, the product could spoil quickly and become unsafe to apply.

Common Preservatives:

5. Fillers

Fillers play an important role in makeup by adding bulk and creating a smooth texture, which helps the product apply evenly. They also determine the product’s finish, whether it’s matte, satin, or glossy.

While fillers don’t contribute color or scent, they are key to how the makeup feels and performs on the skin.

For instance, talc is widely used in powder products like eyeshadow and setting powder. It provides a silky texture and ensures easy blending on the skin. Mica, another common filler, can add a subtle shimmer, while silica is often included to control oil and achieve a matte finish.

Common fillers:

6. Fragrances

Fragrances are added to makeup to give it a pleasant scent, enhancing the overall user experience. These scents can range from floral to fruity, depending on the product and brand. While fragrances make the product more enjoyable to use, they don’t contribute to the makeup’s performance on the skin.

For example, a subtle rose scent might be added to a face powder, or a vanilla fragrance might be included in a lip gloss.

7. Additives

Additives are included in makeup to provide extra benefits beyond the basic function of the product. They can improve texture, offer skincare benefits, or enhance the product’s stability.

Often they are used for marketing purposes as well, and act as a so-called “hero ingredient”.

For example, hyaluronic acid might be added to a foundation for extra hydration, while vitamin E could be included in a lipstick to provide antioxidant protection and help keep lips soft.

The Manufacturing Process of Makeup

The process of making makeup is complex.

What follows is a rough overview of the most important stages, giving you a glimpse into how raw materials are turned into the final product.

1. Formulation

The first step in manufacturing makeup is the formulation process. Chemists determine the exact combination of ingredients needed to achieve the desired result, whether it’s the right shade for a lipstick or the perfect texture for a foundation.

They measure and test different ratios of pigments, emollients, binders, and other ingredients.

Each component is selected for its specific role in the final product, aiming to meet the required color, texture, and performance.

2. Mixing

After the formulation is complete, the ingredients are mixed together in large industrial mixers.

This step is essential for creating a uniform blend, so that every batch of the product is consistent.

For instance, when making foundation, pigments must be evenly dispersed throughout the base to avoid streaks or uneven coverage. The mixture is continuously stirred and sometimes heated to fully integrate all ingredients.

3. Heating (optional)

In some makeup products, heating is an important step. Ingredients like waxes and oils often need to be melted to blend properly.

In lipstick production, the waxes and oils are heated until they become a liquid mixture. This step helps combine all the components smoothly, creating a consistent texture and color throughout the product.

4. Molding and Shaping

After heating and mixing, the liquid mixture is ready to be molded or shaped.

This step is very different from product to product.

For products like lipsticks, the hot liquid is poured into molds to form the desired shape. In this case, the mixture takes on the familiar lipstick form while it is still warm.

For powders, the mixture is pressed into pans under controlled pressure to achieve a compact, solid form.

5. Cooling (optional)

Once the product has been molded or shaped, it is then cooled to solidify. Cooling is done at a controlled rate to prevent defects like cracking or separating.

This step is particularly important for products like lipsticks, where the cooling process solidifies the product into its final form, making it ready for use.

6. Filling and Packaging

The final step in the production process is filling and packaging.

Solid products, like lipsticks or pressed powders, are placed into their cases or compacts.

Liquid products, such as foundations or mascaras, are filled into bottles or tubes.

Once filled, the products are sealed, labeled, and made ready for distribution, giving them the finished appearance that consumers expect.

Ready to Take The Next Step?

Now you know how makeup is made — from selecting the right ingredients to the final touches in packaging. Every stage plays a key role in making sure the makeup not only meets aesthetic standards but also delivers the performance you expect.

As experts in cosmetic manufacturing, we’re here to help you bring your own makeup line to life with the same level of detail and care.

Ready to take the next step? Contact us today for a free quote, and let’s start creating something amazing together.

More Useful Guides

![White Label Cosmetics Explained: Pros & Cons in 2025 [+Guide]](https://www.spypharma.com/uploads/blog/white-label-cosmetics-explained.jpg)

White Label Cosmetics Explained: Pros & Cons in 2025 [+Guide]

![Top 17 Cosmetic Manufacturers for Beginners in 2025 [+Guide]](https://www.spypharma.com/uploads/blog/top-17-cosmetics-manufacturers-for-beginnerstop-17-cosmetics-manufacturers-for-beginners.jpg)

Top 17 Cosmetic Manufacturers for Beginners in 2025 [+Guide]

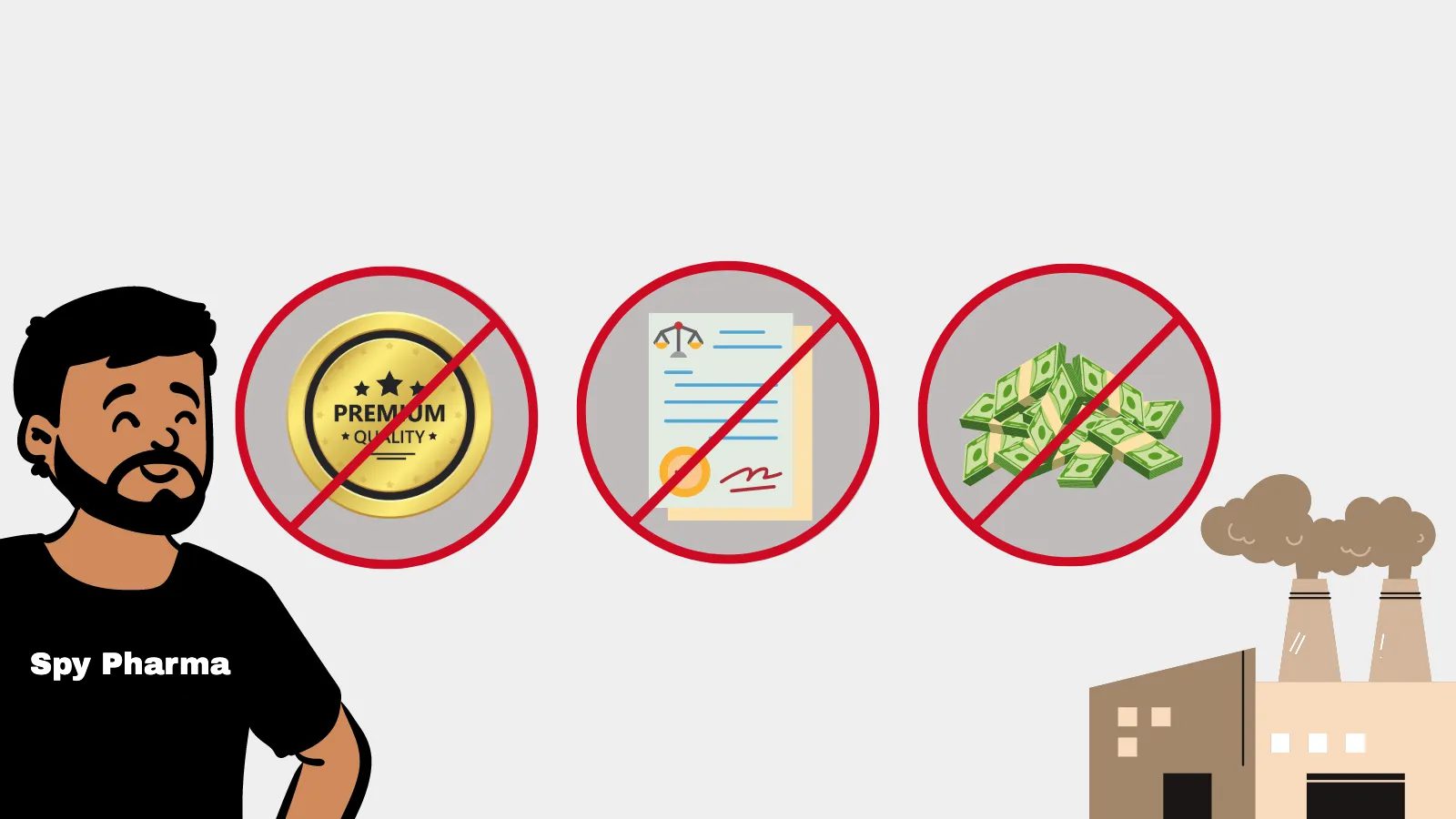

Low MOQ Cosmetic Manufacturers: Be Aware of These Dangers

Ultimate Guide for Vegan Private Label Cosmetics in 2024

![Top 9 Luxury Private Label Cosmetics Manufacturers [+Guide]](https://www.spypharma.com/uploads/blog/luxury-private-label-cosmetics-manufacturers.jpg)

Top 9 Luxury Private Label Cosmetics Manufacturers [+Guide]

![Starting a Lip Gloss Business: A Step-by-Step Guide [2025]](https://www.spypharma.com/uploads/blog/starting-a-lip-gloss-business.jpg)