How do brands like MAC, Dior, and Fenty Beauty produce their cosmetics?

In most cases, makeup and skincare products are not manufactured in-house but are produced with the help of a cosmetic contract manufacturer.

It’s very common in the cosmetics industry to collaborate with third-party manufacturers for product creation. Setting up your own production line is a significant challenge, and in most cases, it’s neither feasible nor economically viable.

Partnering with a contract manufacturer for your cosmetic products saves you time and money, allowing you to focus on developing your brand.

Before we dive into a detailed guide on everything related to contract manufacturing in the cosmetics industry, let’s first take a look at our top 21 contract manufacturers in USA and Europe.

Top 17 OEM Cosmetic Manufacturer

| Rank | Name | Country |

|---|---|---|

| 1 | Spy Pharma | Turkey🇹🇷 |

| 2 | Oxygen Development | USA 🇺🇸 |

| 3 | Cosmetic Solutions | USA 🇺🇸 |

| 4 | Lady Burd | USA 🇺🇸 |

| 5 | Cosmopak | USA 🇺🇸 |

| 6 | Garcoa | USA 🇺🇸 |

| 7 | SystemKosmetik | Germany 🇩🇪 |

| 8 | PakLab | USA 🇺🇸 |

| 9 | Tri-Pac | USA 🇺🇸 |

| 10 | Verla International | USA 🇺🇸 |

| 11 | HCT | USA 🇺🇸 |

| 12 | Sheen Color | USA 🇺🇸 |

| 13 | Mascara Plus | Italy 🇮🇹 |

| 14 | Cosmetique SA | Switzerland 🇨🇭 |

| 15 | Ariel Labs | USA 🇺🇸 |

| 16 | Beauty Manufacturing Solutions Corp. | USA 🇺🇸 |

| 17 | ColorStrokes Cosmetics | USA 🇺🇸 |

| 18 | Skinovators | Germany 🇩🇪 |

| 19 | McKenna Labs | USA 🇺🇸 |

| 20 | Temmentec AG | Switzerland 🇨🇭 |

| 21 | ItIt Cosmetics | Italy 🇮🇹 |

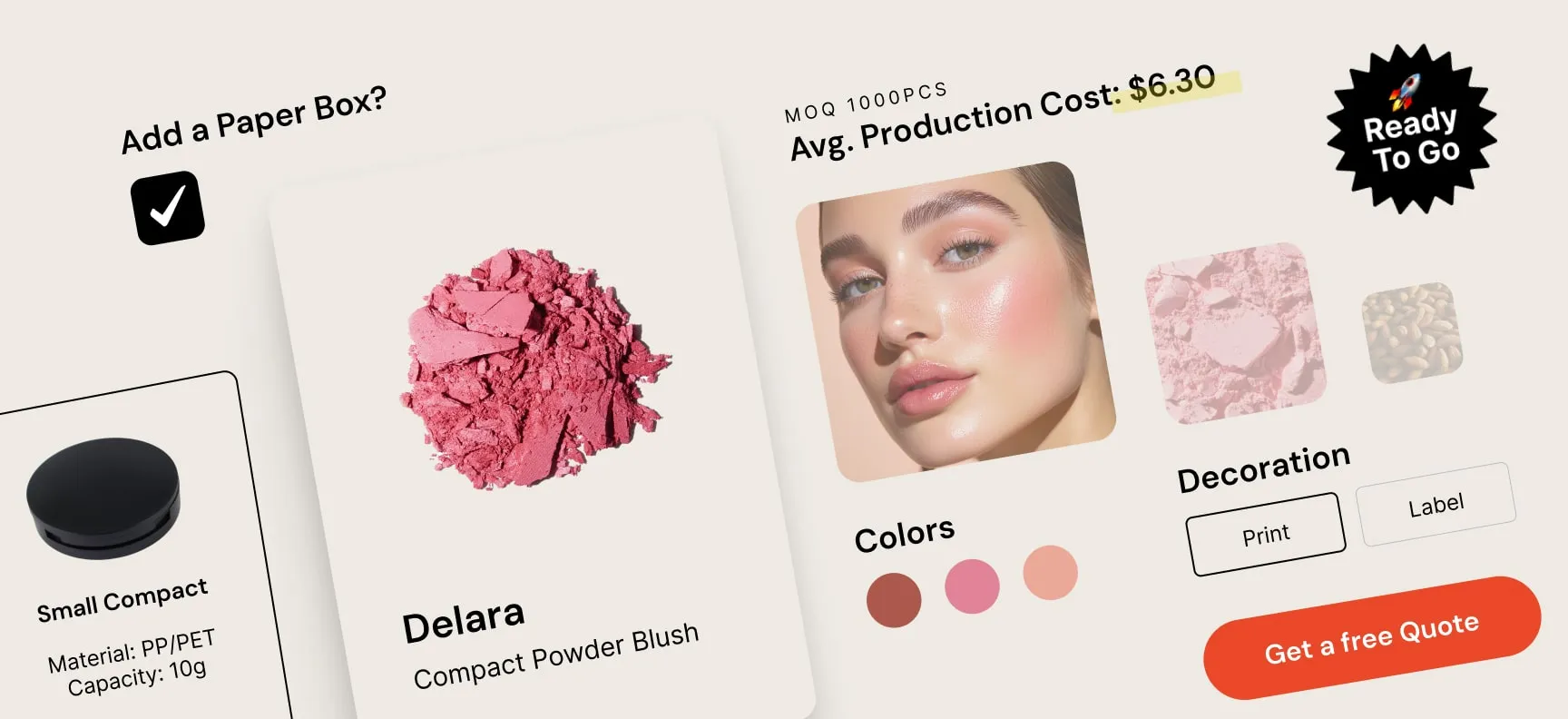

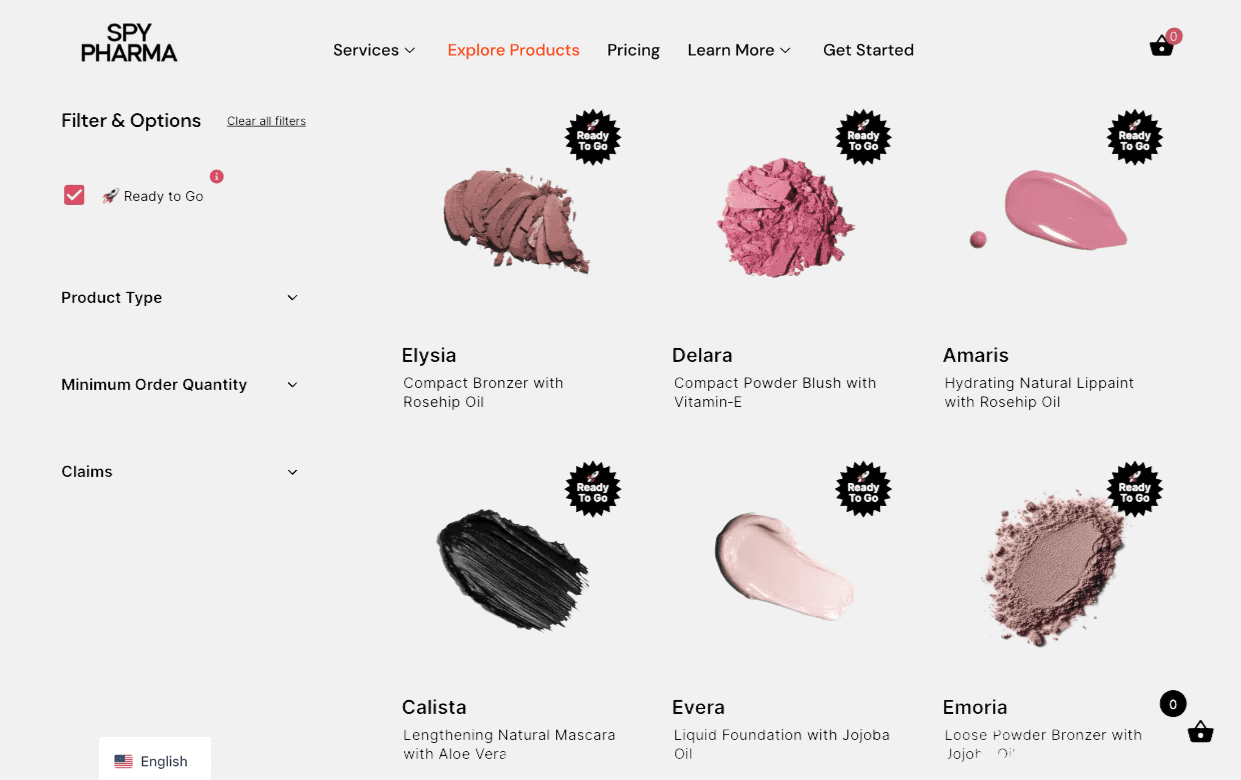

1. Spy Pharma

At Spy Pharma, we offer comprehensive solutions for creating your own cosmetic products.

While we don’t handle the filling process ourselves, we focus on providing a wide range of products, numerous private label formulations, and top-notch services for brand development, product design, and more.

Our diverse packaging options allow you to customize pre-made formulations with unique packaging tailored to your brand.

Leveraging our network of specialized suppliers and contract fillers, we offer flexible and cost-effective production options, supporting you from product development to market launch. We also provide extensive regulatory support, often with a minimum order quantity of just 250–1,000 units per product.

2. Oxygen Development

Oxygen Development specializes in contract manufacturing for lipsticks and compact powder. They emphasize high quality with certifications like ISO 22716 (GMP), EcoVadis, and IFS-HPC.

Their services cover consulting, formula development, packaging, bulk production, and assembly. They highlight its German manufacturing standards and commitment to sustainability.

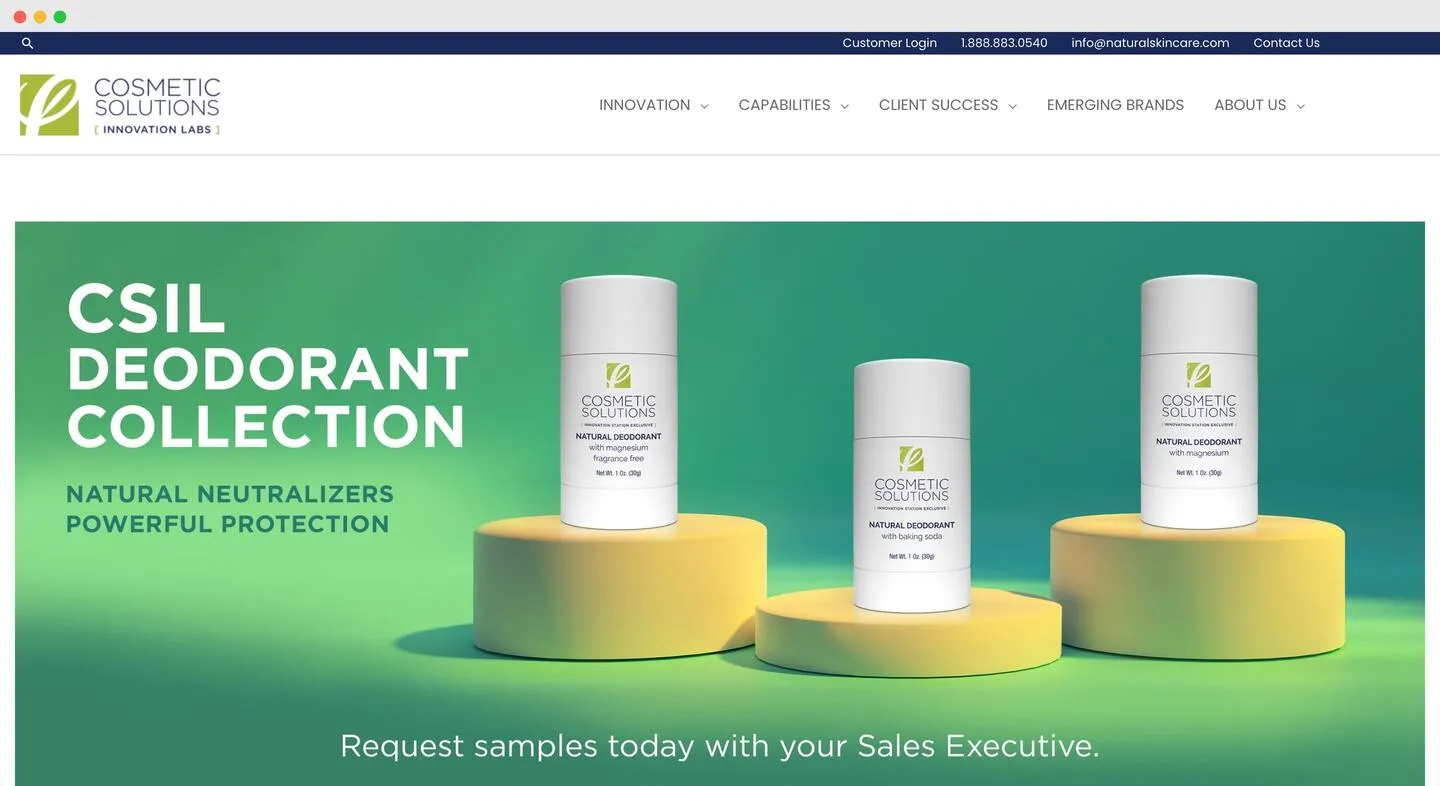

3. Cosmetic Solutions

Cosmetic Solutions offers turnkey contract manufacturing, specializing in organic, natural, and high-tech skincare. They cater to various clients, including dermatologists and spas. The company is ISO 22716 certified and FDA-registered, ensuring high manufacturing standards.

They support emerging brands with in-stock products and offer full branding and packaging services. Their innovation team works closely with clients for custom solutions, with a focus on speed to market and quality.

4. Lady Burd

Lady Burd is a cosmetic contract manufacturer offering a wide range of products, including skincare, makeup, and personal care. They provide low Minimum Order Quantities (MOQs), starting at $150 for stock items or 12 pieces per shade for private label.

Their services include custom formulation, full-color custom labels, and packaging. Lady Burd is known for its high-quality, American-made products, manufactured in New York. They also offer turnkey services, including design and branding support, making it easy for new brands to launch.

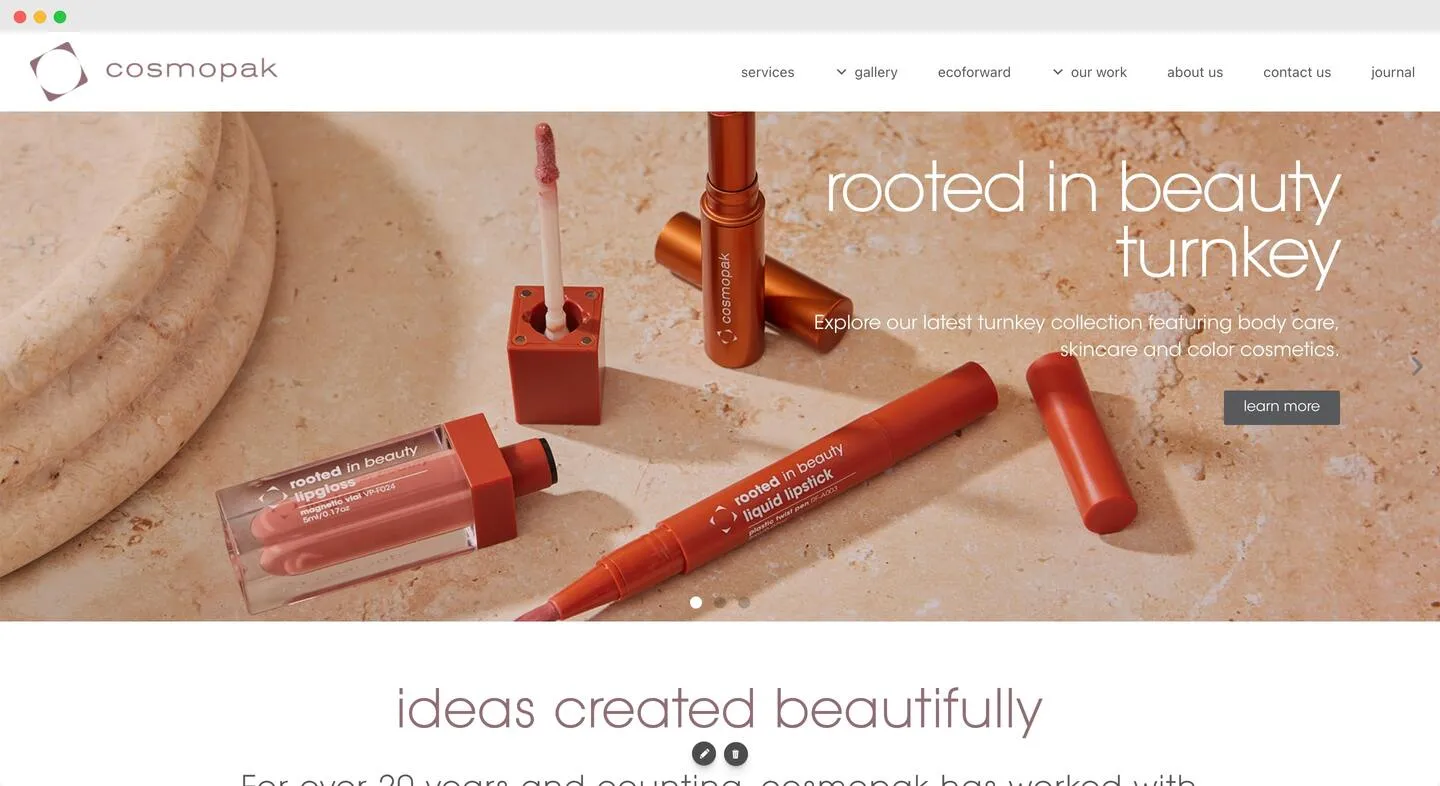

5. Cosmopak

Cosmopak specializes in designing, developing, and manufacturing beauty products. They provide turnkey services covering everything from custom formulations to accessories like bags and boxes.

Sustainability is a key focus, with eco-friendly packaging options available. The company supports brands at various stages, from emerging to established, and emphasizes high customization and flexibility to meet specific brand needs.

6. Garcoa

Garcoa offers comprehensive private label and contract manufacturing services across health, beauty, OTC, and cleaning categories. With over 1 million square feet of space and 66 production lines across five North American facilities, they are equipped to handle large-scale production. Garcoa emphasizes innovation, sustainability, and quality, aiming to be carbon neutral by 2025.

Their services include product development, engineering, creative design, and marketing support.

7. SystemKosmetik

SystemKosmetik is a German contract manufacturer with over 35 years of experience, certified according to ISO 9001, ISO 14001, and GMP standards.

They produce conventional, natural, and medical cosmetics, offering flexible production sizes ranging from 30 kg to 4,000 kg, along with various packaging options.

SystemKosmetik also provides private label solutions and offers comprehensive after-sales services.

8. PakLab

PakLab is unique for its expertise in creating highly customized and complex formulations, particularly in the skincare and haircare sectors. PakLab differentiates itself with its strong R&D capabilities and the ability to handle niche, high-performance products.

Their flexibility and technical know-how make them a go-to for brands needing specialized formulations that aren’t easily found elsewhere.

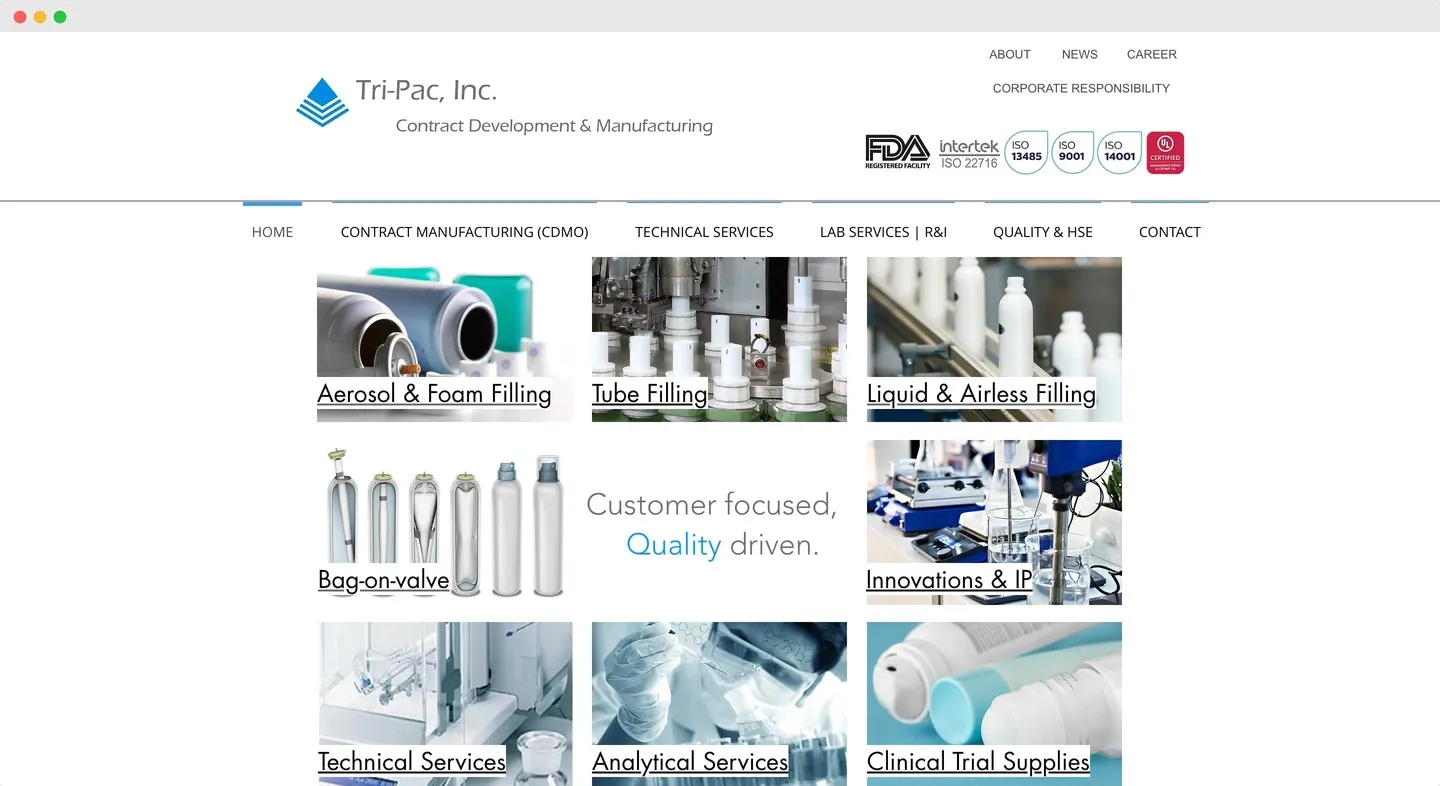

9. Tri-Pac

Tri-Pac stands out for its focus on aerosol, liquid, and gel manufacturing with advanced capabilities in blending, filling, and packaging. They are particularly strong in handling regulated products like EPA and FDA-approved items.

Tri-Pac offers custom formulation and turnkey solutions, with a particular emphasis on speed and efficiency in bringing products to market.

10. Verla International

Verla offers color cosmetics and skincare, with a particular strength in innovation and product development. They are notable for its in-house research and development team, which works closely with clients to create custom formulas tailored to specific market demands.

Their emphasis on rigorous testing and quality assurance ensures that products meet the highest standards before reaching the market.

11. HCT

HCT provides end-to-end solutions for beauty brands, including packaging, formulation, and manufacturing. They offer a wide range of products, from skincare and color cosmetics to fragrance and accessories.

They work with both emerging and established brands, providing services from concept to shelf. Their global presence ensures high-quality standards and efficient production across different markets.

12. Sheen Color

Sheen Color specializes in producing high-quality color cosmetics with a strong focus on trend-driven, fashion-forward products.

Their strength lies in rapid development cycles, allowing for quick adaptation to new trends and customer demands. Sheen Color Group also provides comprehensive services from product conception to final production, ensuring a seamless process for their clients.

13. Mascara Plus

Mascara Plus is focused exclusively on color cosmetics (products like lipsticks, eyeshadows, and foundations). They operate out of Milan, Italy, leveraging their location in the fashion capital to stay at the forefront of beauty trends. What sets them apart is their in-house R&D team, which collaborates closely with clients to deliver customized, on-trend products with precise color matching and innovative textures.

They focus on luxury private-label manufacturing with a deep commitment to quality and innovation.

14. Cosmetique SA

Cosmetique SA is one of the leading cosmetic contract manufacturers based in Switzerland. They offer a range of services, including development, production, filling, and storage.

The company is certified according to ISO 9001:2015 and ISO 22716 (GMP for cosmetics), ensuring the highest quality standards. Their product range includes makeup removers, nail polish removers, skincare products, and various cleansing wipes.

With over 125 years of experience in the cosmetics industry, Cosmetique SA provides tailored solutions for both small and large-scale productions, making them a trusted partner in the field.

15. Ariel Labs

Ariel Laboratories, based in New Jersey, specializes in the development and manufacturing of custom skincare, color cosmetics, and sun care products. With over 35 years of experience, they offer a comprehensive range of services, including formulation, production, and packaging, supported by strong customer service and compliance with international regulations.

Ariel Laboratories is ISO certified and GMP compliant, ensuring high-quality standards for their clients, which range from small businesses to large multinational companies.

16. Beauty Manufacturing Solutions Corp.

Beauty Manufacturing Solutions specializes in private label and contract manufacturing for beauty and skincare products. They offer services from concept development to full production, including formulation, packaging, and regulatory support.

Their product range includes skincare, haircare, and body care products, with a focus on natural and organic ingredients.

17. ColorStrokes Cosmetics

ColorStrokes offers makeup brushes and color cosmetics like blushes, eyeshadows, and foundations. While you can start with just 3 units per product when choosing one of their on-stock-products, their minimum order quantity for a custom packaging starts at 2000 units per product.

All of their products are 100% made in USA, cruelty-free, vegan and paraben-free,

18. Skinovators

Skinovators, a part of the KLAPP Group, is a leading German contract manufacturer specializing in private label cosmetics. According to their own statements, they offer over 400 existing formulations with the option for customized adjustments.

They also provide a wide range of services, including packaging design, regulatory support, and global logistics.

Their full-service approach covers skincare, all types of color cosmetics, and health cosmetics. However, a potential drawback for many could be their high minimum order quantity of 10,000 units.

19. McKenna Labs

McKenna Labs is a contract manufacturer specializing in personal care products, including skincare, haircare, and more. They offer end-to-end services, from product formulation and development to manufacturing and packaging.

They also offer research and development capabilities, allowing for customized product solutions.

20. Temmentec AG

Temmentec, a Swiss contract manufacturer based in Sumiswald, offers comprehensive services in cosmetic production.

They specialize in developing custom formulations, conducting necessary tests, and providing complete documentation and regulatory compliance. Their production capabilities include emulsions, liquids, waxes, oils, and sticks, with batch sizes ranging from 10 kg to 10,000 kg.

To put this into perspective, 10 kg equates to approximately 330 units with a fill volume of 30 ml.

In addition to manufacturing, they offer services such as packaging and logistics solutions, making them a well-rounded partner for cosmetic production needs.

21. ItIt Cosmetics

iTiT Cosmetics, founded in 2011, is an Italian contract manufacturer specializing in lip, eye, and face products. They offer customized solutions that cover everything from concept development to packaging. The company is certified under ISO 22716 and ISO 9001, ensuring high-quality standards.

One of their key strengths lies in their trend analysis, which drives the creation of innovative makeup formulations based on the latest market trends.

Guide

What are Cosmetic Contract Manufacturers?

First off, it’s important to note that every cosmetics manufacturer seems to use these terms a bit differently, and there’s no universally agreed-upon definition.

The lines between various manufacturing practices are often blurred, making it challenging to draw clear distinctions.

Nevertheless, we’d like to share our understanding with you.

Definition of Cosmetic Contract Manufacturers

At their core, contract manufacturers are companies that produce, fill, or package cosmetic products.

In many cases, these manufacturers also take on product development and raw material sourcing for you.

When applied to cosmetics manufacturing, this means contract manufacturers fill the formulation into packaging and deliver the finished product to you. You can either opt for an in-house formulation and packaging provided by the manufacturer, or supply them with your own.

At Spy Pharma, we have an extensive network of contract manufacturers for a wide range of cosmetic products. Once you’ve chosen one of our formulations and packaging options, we commission them to produce the final product.

What’s the Difference Between Contract Manufacturing and Private Label Cosmetics?

Private label cosmetics primarily refer to pre-made products that are branded with your logo and design. These products can either be already manufactured and in stock (often referred to as white label cosmetics) or produced on demand.

In any case, the formulation and packaging are predetermined.

This is the key difference from contract manufacturing in the cosmetics industry. With contract manufacturing, both the formulation and packaging can be freely chosen or even newly developed.

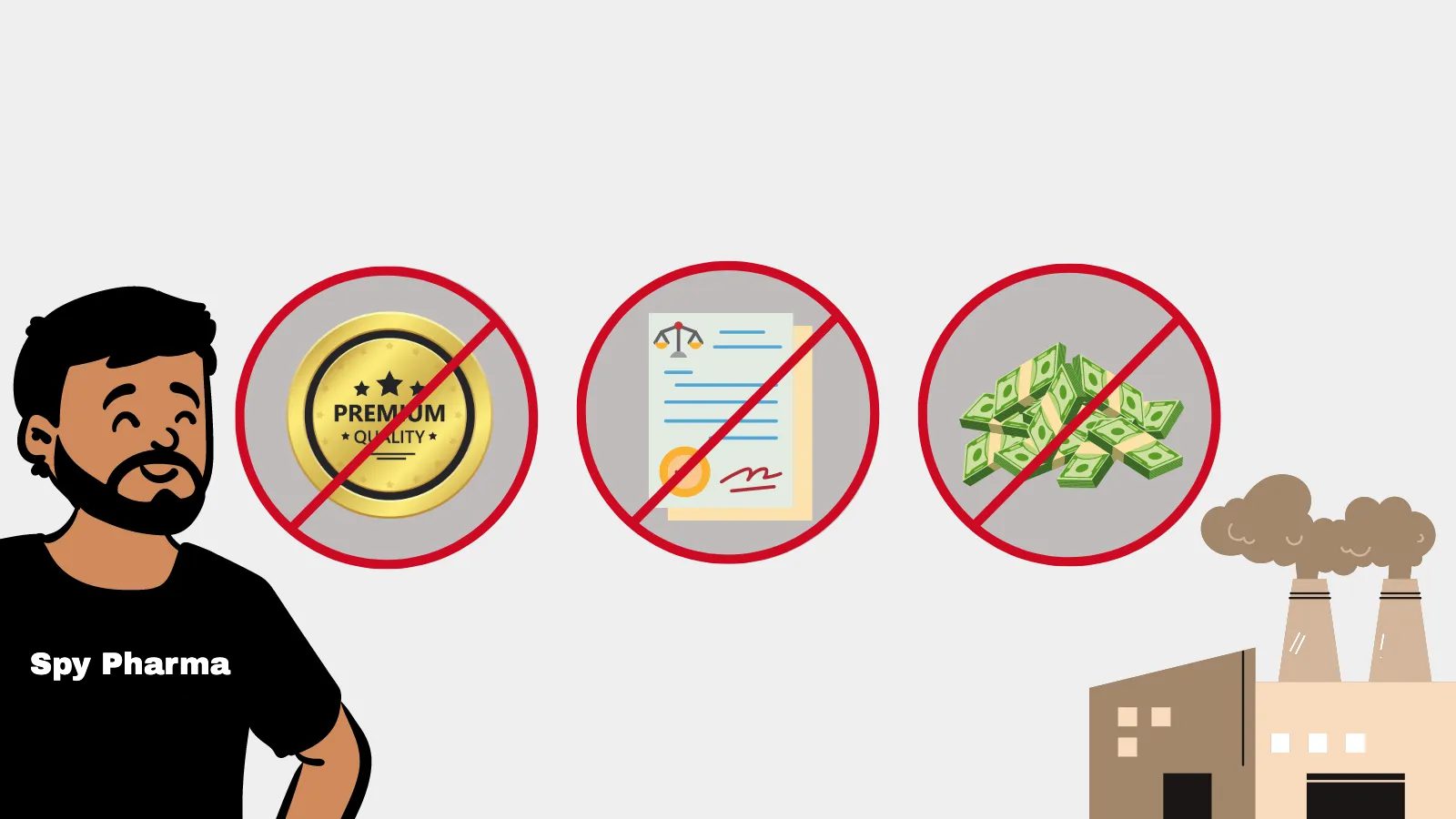

How to Choose the Right Cosmetic Contract Manufacturer

So, let’s say you decide to work with a pure contract manufacturer for cosmetics (and not with us 🥲).

Having worked closely with numerous cosmetic contract manufacturers for many years, we understand the challenges and know what’s important.

Here’s a checklist of what you should pay attention to!

1. Product Range

There’s a wide variety of cosmetic products, and contract manufacturers typically specialize in a specific area.

This specialization makes sense because producing lipsticks, mascaras, and day creams involves very different machines and processes.

If you’re planning to start with a small cosmetics line, you’ll likely need to work with several different contract manufacturers—especially if you plan to expand your product line later.

Be aware of the additional effort this entails, particularly in terms of communication and overall procurement.

That’s why it’s wise to look for a contract manufacturer that can cover as many products from your planned product range as possible right from the start.

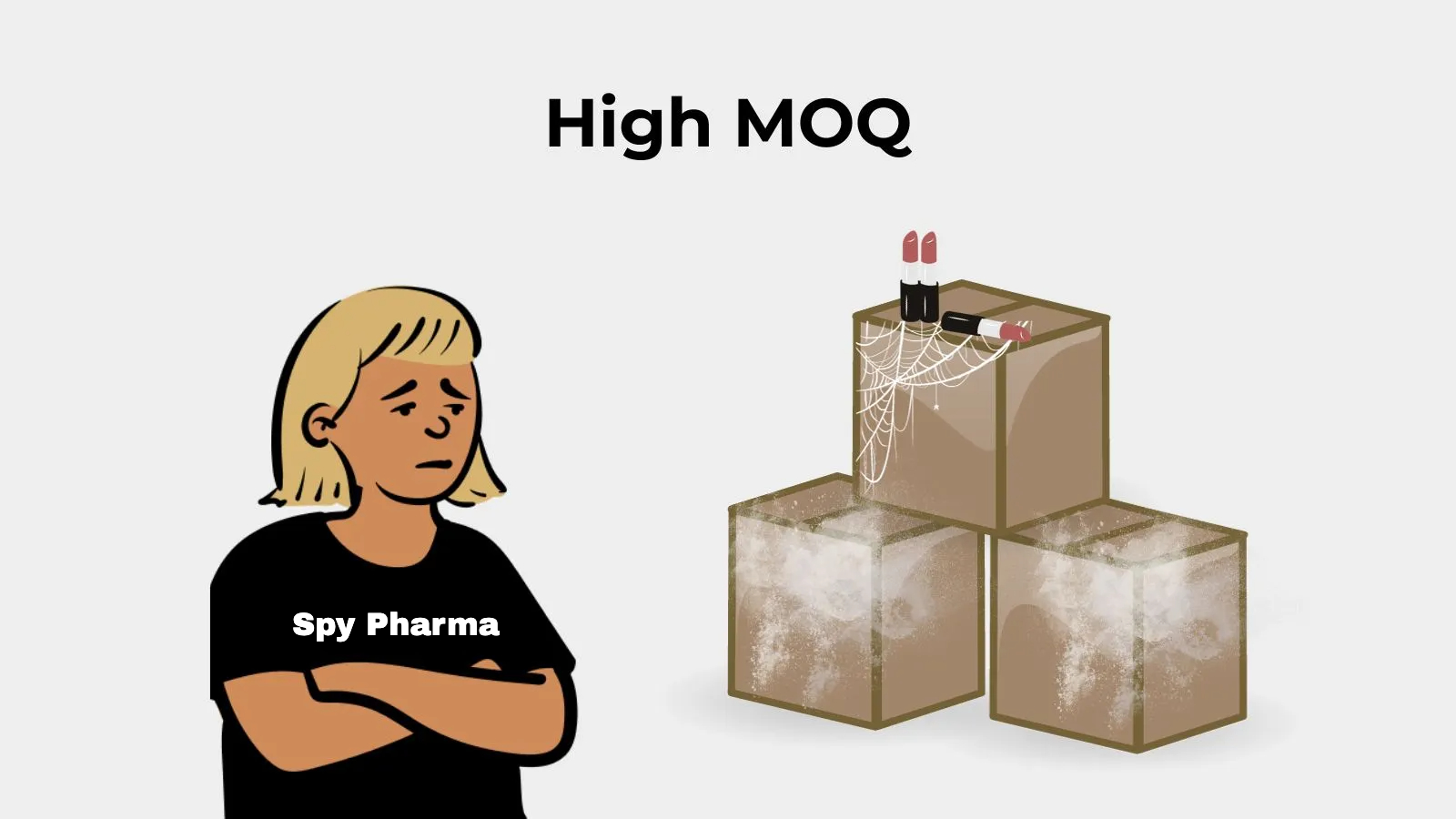

2. Minimum Order Quantity (MOQ)

One of the biggest fears for any entrepreneur is being stuck with unsold products.

This is why many prefer to start with the smallest possible order quantity, even though this generally means higher unit costs.

Here’s where a conflict arises:

While customers want to order the smallest quantity possible at the beginning (to minimize risk), the contract manufacturer needs to produce a pretty large minimum quantity to sell the products at a reasonable and profitable price.

This is simply due to the way manufacturing machines and processes are designed—they are set up to handle a certain minimum volume. Falling below this threshold makes the final product disproportionately expensive.

So, it’s crucial to ask the contract manufacturer early in the process about their minimum order quantity (MOQ) for the desired products. For color cosmetics, make sure to check if there’s a MOQ per color as well as an overall MOQ for the entire order.

At Spy Pharma, we offer lower minimum order quantities than most cosmetic contract manufacturers. We achieve this by combining orders from different customers and securing binding contracts with our manufacturers for annual minimum purchase quantities.

3. Costs per Unit

The unit cost is the price a contract manufacturer charges you per product produced.

These costs are influenced by numerous factors, but the three most important are:

- Formulation or the cost of individual ingredients

- Packaging

- Complexity of the manufacturing process and filling

This figure is crucial for a brand because it ultimately determines the selling price and profit margin of your products.

You should always consider the unit cost in relation to the order quantity, as it typically decreases with larger orders.

It’s possible that your first order, at the minimum quantity, may not yield much profit after all costs are deducted. However, as your order quantity increases, the unit cost could be nearly halved, allowing you to achieve a profitable margin.

4. Time-to-Market

Production time refers to the period between placing an order and the completion of the production.

It’s important to note that the contract manufacturer can only begin production once they have your finalized print data, meaning the product design (if they are responsible for printing or labeling your products).

This means you should finalize and send your product design to the manufacturer as early as possible to avoid any additional delays between placing the order and the start of production.

To save time, you might consider asking the cosmetic contract manufacturer about private label formulations.

This can save you up three to six months of development time for a new formulation. Additionally, private label cosmetics generally do not require additional tests, such as stability and compatibility testing.

These are just tricks to shorten the time until production starts. However, it’s still crucial to choose a contract manufacturer with production timelines that fit your schedule.

While most cosmetic manufacturers have production times ranging from 8 to 12 weeks, with particularly renowned contract manufacturers, you might need to plan for up to 9 months for production!

5. Certifications

When selecting a contract manufacturer for your cosmetic products, it’s vital to ensure that they comply with both local and international regulations for cosmetic manufacturing.

You should especially consider the regulations of your target market. In Europe, these regulations are harmonized across countries but differ significantly from those in the United States.

Therefore, before choosing a contract manufacturer, you should ask yourself:

Where do I want to sell my cosmetic products?

In general, contract manufacturers based in Europe adhere to the strictest guidelines and quality standards. This means that your products are usually marketable worldwide (with possibly minor adjustments to the formulation or labeling) if they are manufactured in Europe.

Make sure to confirm the marketability of your products with the potential contract manufacturer before starting production.

They should also assure you that they will provide the necessary documents, such as the Safety Data Sheet (SDS) required in Europe.

6. Additional Services

Depending on your goals and how your team is set up, it might be beneficial if the cosmetic contract manufacturer offers services beyond just filling or producing the products.

A contract manufacturer that provides services like developing new formulations, brand development and design, product design, or logistics is often referred to as a full-service contract manufacturer.

We can’t give a definitive recommendation on which services you should prioritize. This depends heavily on your individual needs.

For example, a distributor with an existing brand might look for a contract manufacturer to produce their existing formulations, while a new entrepreneur without design expertise may highly value brand design services.

In our view, brand and product design play a crucial and often underestimated role in the cosmetics industry, which is driven by aesthetics and beauty. That’s why we have a top-notch design team that specializes entirely in the cosmetics industry and its aesthetic demands.

More Useful Guides

![White Label Cosmetics Explained: Pros & Cons in 2025 [+Guide]](https://www.spypharma.com/uploads/blog/white-label-cosmetics-explained.jpg)

White Label Cosmetics Explained: Pros & Cons in 2025 [+Guide]

![Top 17 Cosmetic Manufacturers for Beginners in 2025 [+Guide]](https://www.spypharma.com/uploads/blog/top-17-cosmetics-manufacturers-for-beginnerstop-17-cosmetics-manufacturers-for-beginners.jpg)

Top 17 Cosmetic Manufacturers for Beginners in 2025 [+Guide]

Low MOQ Cosmetic Manufacturers: Be Aware of These Dangers

Ultimate Guide for Vegan Private Label Cosmetics in 2024

![Top 9 Luxury Private Label Cosmetics Manufacturers [+Guide]](https://www.spypharma.com/uploads/blog/luxury-private-label-cosmetics-manufacturers.jpg)

Top 9 Luxury Private Label Cosmetics Manufacturers [+Guide]

![Starting a Lip Gloss Business: A Step-by-Step Guide [2025]](https://www.spypharma.com/uploads/blog/starting-a-lip-gloss-business.jpg)

![Top 21 Cosmetic Contract Manufacturers in USA & Europe [+Guide]](https://www.spypharma.com/uploads/blog/cosmetic-contract-manufacturers.jpg)